Elevate Your Brushing Solutions with Aviva Brushes

Discover Our Premier Industrial Brush Services

Extending the Efficiency of Your Industrial Brushes

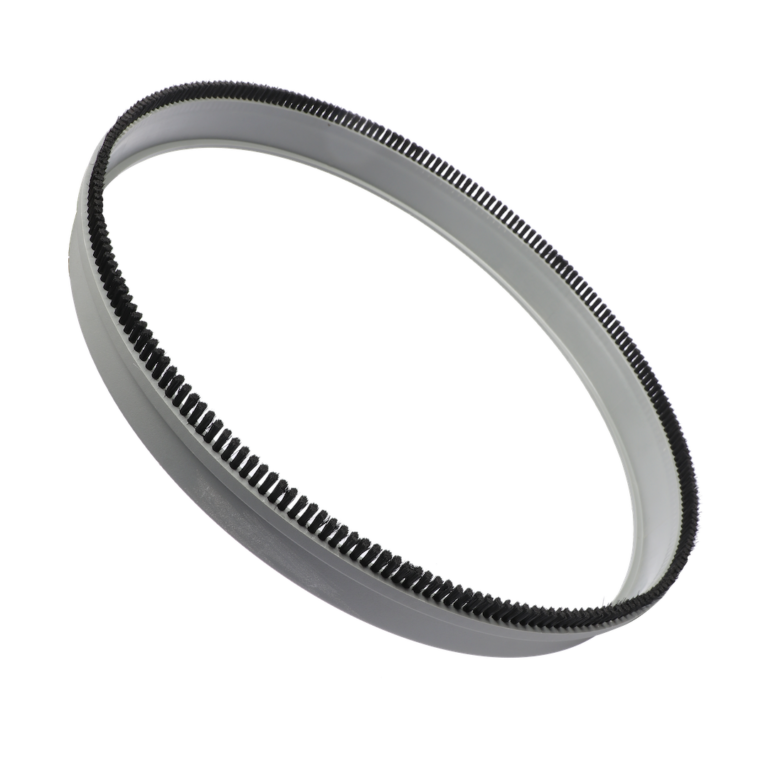

Unmatched Industrial Brush Solutions

Industrial Brush Manufacturing

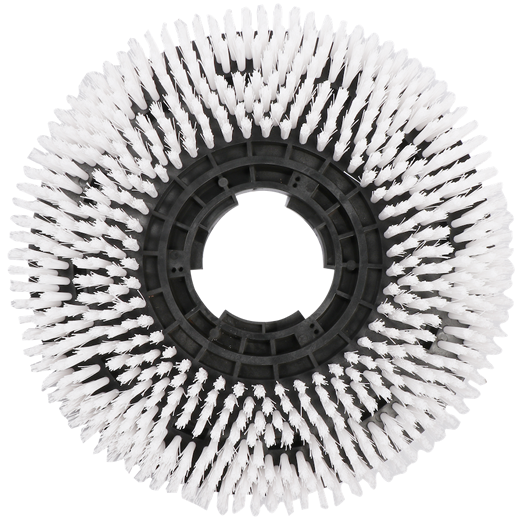

Floor & Maintenance Solutions

Enhance the Performance of Your Industrial Brushes With Custom-Built Brush Solutions

Extended Brush Life

Reduced Downtime

Substantial Cost Savings

Why Industrial Brush Maintenance Matters

Importance of Industrial Brush Maintenance Services

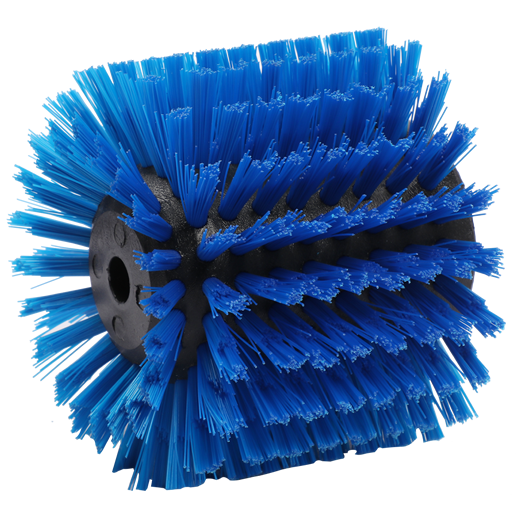

Enhanced Brush Efficiency

Our Reworking Services at Aviva Brushes are designed to enhance your brush’s efficiency like never before. We don’t just refurbish; we optimize your brushes to operate at peak performance. Say hello to brushes that work smarter, not harder

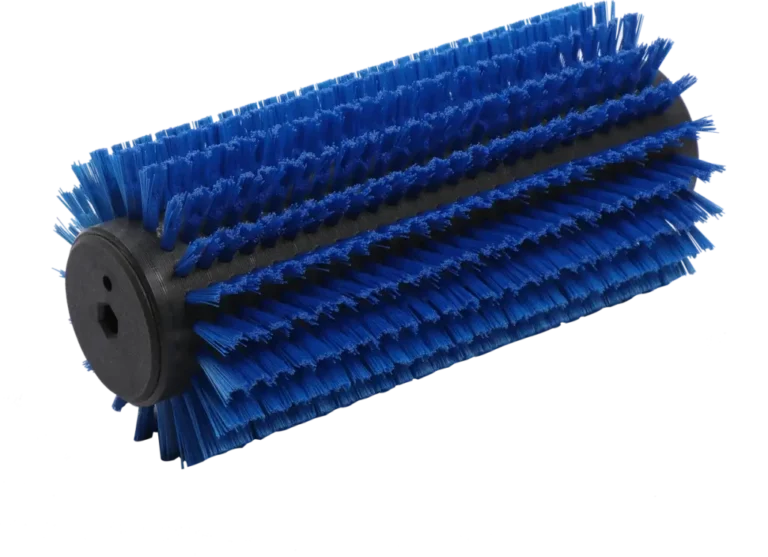

Reduced Maintenance

With Aviva Brushes, you’ll enjoy reduced maintenance hassles. Our reworking services ensure that your brushes remain reliable for longer periods, minimizing the need for constant upkeep and saving you valuable time and resources with industrial brush maintenance service.

Increased Productivity

Aviva Brushes’ reworking services aren’t just about maintaining; they’re about improving. Experience a significant boost in your output as your brushes perform at their best, contributing to higher productivity levels and a more efficient operation.

Let's Elevate Your Brushing Solutions Together

Reach out to our expert team today. We’re here to tailor our premier industrial brush services to your unique needs with industrial brush tufting services.