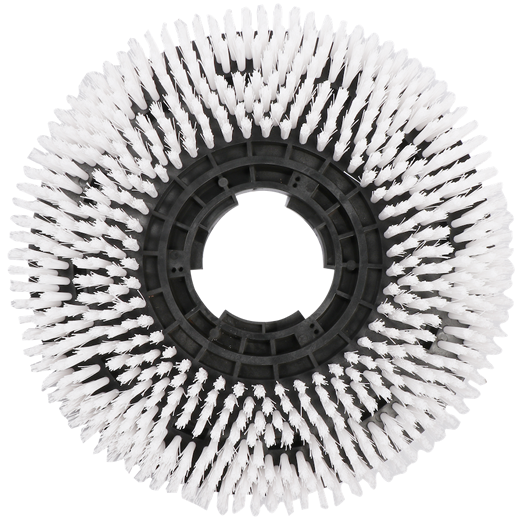

In the dynamic industrial landscape, the performance and durability of tools like industrial brushes are pivotal for productivity. Aviva Brushes provides a comprehensive guide to effectively maintain these essential tools. Our latest blog highlights key maintenance strategies crucial for prolonging brush lifespan and maintaining peak efficiency. Covering effective cleaning techniques and proper storage and handling, these insights are crucial for anyone aiming to maintain their brushes’ quality and functionality. Ideal for various applications, from heavy-duty cleaning to precision tasks, this guide is your resource for keeping Aviva Brushes in top condition, ensuring seamless operations and optimal results in your industrial projects.

Understanding your Brush’s Needs:

At Aviva Brushes, we recognize that different industrial brushes have unique maintenance needs, vital for their longevity and efficiency. Heavy machinery brushes might require frequent upkeep due to harsh usage, whereas brushes for electronics need delicate cleaning to protect their bristles. Understanding the specific type and application of your brush is key to appropriate care. Whether it’s a wire brush for rust removal or a nylon brush for delicate dusting, each requires tailored maintenance. Regular wear checks for abrasive brushes and gentle cleaning for softer types are crucial. Customized care ensures your Aviva Brushes perform optimally, enhancing efficiency and smooth operations in production.

Cleaning and Storage Practices:

Maintaining the integrity and extending the lifespan of your industrial brushes from Aviva Brushes hinges significantly on proper cleaning and storage practices. Effective cleaning not only preserves the quality of the brush but also ensures its efficiency in every use.

For cleaning, it’s vital to choose a method that corresponds with the brush’s material. For synthetic bristles, lukewarm water with mild detergent works well, while natural fibers may require different care to avoid damage. After cleaning, thoroughly rinse to remove any soap residue. Be gentle during the cleaning process to prevent bristle damage. It’s also important to dry brushes correctly. Avoid direct heat sources; instead, let them air dry to maintain bristle integrity.

Regarding storage, proper organization plays a critical role. Brushes should be stored in a manner that prevents bristle deformation. Hanging brushes vertically is often the best way to maintain their shape. It’s also crucial to store them in environments free from extreme temperatures and humidity, which can degrade materials over time.

By implementing these cleaning and storage practices, you can significantly prolong the life and preserve the efficiency of your Aviva Brushes. Regular and correct maintenance not only saves costs in the long run but also ensures consistent performance for all your industrial applications.

Regular Inspection and Maintenance:

Routine inspection and maintenance are vital for the optimal performance of industrial brushes. Regularly checking your Aviva Brushes for wear and tear extends their lifespan and maintains efficiency in industrial processes.

During these inspections, focus on signs of bristle wear, such as uneven or reduced bristle length, which can impact the brush’s effectiveness. Also, look for damage to the brush body or handle, which can affect its functionality and safety. For brushes used in harsh environments or with abrasive materials, checking for bristle integrity is crucial. Frayed or broken bristles can significantly reduce cleaning or processing efficiency.

When assessing whether a brush needs maintenance or replacement, consider its current performance compared with when it was new. If a brush is no longer performing its task effectively or shows signs of significant wear, it’s time for maintenance or a replacement. Cleaning the brush might restore its functionality, but if wear is too extensive, replacing the brush is often more cost-effective and ensures optimal performance.

Regular inspections and timely maintenance or replacements prevent downtime and productivity loss, upholding Aviva Brushes’ commitment to quality and efficiency.

Avoiding Common Mistakes:

Maintaining industrial brushes correctly is key to preserving their effectiveness and longevity. At Aviva Brushes, we highlight common maintenance errors to avoid:

- Over-Cleaning: Excessive cleaning or harsh chemicals can damage bristles. Opt for gentle cleaning agents and methods appropriate for your brush’s material.

- Improper Storage: Incorrect storage can deform bristles and impair brush performance. Store brushes to maintain their shape, in dry and temperate conditions.

- Moisture Management: Brushes should be thoroughly dried post-cleaning to prevent mold and bristle degradation. Avoid storing damp brushes.

- Regular Inspections: Frequently check your brushes for wear and tear. This practice helps determine when a brush needs care or replacement, preventing breakdowns.

- Task-Specific Usage: Using one brush for multiple tasks can lead to premature wear. Utilize brushes as designed for their specific functions.

By steering clear of these pitfalls, you significantly enhance the lifespan and efficiency of your Aviva industrial brushes, ensuring they remain in prime condition for their intended use.

Leveraging Expert Advice:

Maintaining industrial brushes, especially those designed for specialized tasks, often requires more than just a basic understanding of care procedures. This is where expert advice becomes invaluable. We understand the intricacies involved in maintaining different types of industrial brushes and we’re committed to providing our clients with the expertise and support they need.

For those handling complex or high-value tasks with our brushes, we highly recommend seeking professional advice for maintenance. This ensures that each brush is cared for in a manner that aligns with its specific design and use. Our team of experts at Aviva Brushes is equipped with the knowledge and experience to guide you through the best maintenance practices, tailored to your specific brush types.

We can advise on the most effective cleaning methods, the appropriate storage solutions, and the optimal frequency of maintenance routines. For brushes that are integral to your operations, such as those used in precision manufacturing or food processing, our guidance can be crucial in prolonging their lifespan and maintaining their efficiency.

Whether you need advice on maintaining a standard brush or a custom-designed one, Aviva Brushes is here to help. Our goal is to ensure that your brushes, and consequently your operations, run smoothly and effectively.

Conclusion:

In conclusion, the maintenance of industrial brushes is not just a routine task; it’s an essential practice that directly impacts their lifespan and efficiency. Remember, effective cleaning tailored to the brush type, proper storage to retain shape and function, regular inspections for wear and tear and avoiding common maintenance mistakes are key to prolonging the life of your Aviva brushes. Proper care ensures these brushes continue to perform optimally in your industrial applications, ultimately contributing to smoother operations and enhanced productivity.

We encourage you to implement these maintenance tips with your Aviva brushes. By doing so, you’ll not only extend the life of your brushes but also maintain their high efficiency. Should you need further guidance or wish to explore our range of durable, high-quality industrial brushes, don’t hesitate to reach out to us. At Aviva, we’re committed to providing you with the best products and support to meet all your industrial brush needs.